Views: 0 Author: Site Editor Publish Time: 2025-06-13 Origin: Site

Wood wool panels have emerged as a sustainable and versatile building material, blending the natural aesthetics of wood with the functional benefits of modern construction technology. These panels are not only environmentally friendly but also offer excellent acoustic and thermal properties. This article delves into the intricate process of creating wood wool panels, providing a comprehensive guide for manufacturers, builders, and enthusiasts interested in this innovative material. Understanding the intricacies of wood panel production is essential for harnessing their full potential in various applications.

The foundation of a high-quality wood wool panel lies in the selection of raw materials. The primary components include wood fibers, commonly sourced from spruce, pine, or aspen due to their optimal fiber characteristics. These fibers are combined with inorganic binders like cement, magnesite, or gypsum to enhance durability and fire resistance. Additives such as water repellents and preservatives may also be incorporated to improve the panel's performance against moisture and pests.

In addition to the core materials, the production process may require molds or forms, pressing equipment, and curing facilities. The choice of binder significantly influences the panel's properties; for instance, cement-bonded panels offer superior strength and fire resistance, while magnesite-bonded panels boast better flexibility and lighter weight. Selecting the appropriate materials is crucial for achieving the desired balance of structural integrity and functional properties in the final Wood Wool Panel.

The first step in manufacturing wood wool panels involves processing the raw wood into fine fibers. Logs are debarked and cleaned to remove impurities that could affect the panel's quality. The wood is then shredded using specialized machines called excelsior machines, which produce thin, ribbon-like strands known as wood wool.

The dimensions of the wood wool strands play a critical role in the panel's characteristics. Typically, strands are cut with widths ranging from 0.1 to 3 mm and lengths from 200 to 500 mm. Controlling the strand size affects the panel's density, thermal conductivity, and acoustic performance. Fine fibers yield denser panels with better thermal insulation, while coarser fibers enhance acoustic absorption by increasing internal porosity. The moisture content of the wood fibers must also be regulated, usually between 8% and 15%, to ensure proper binding with the cementitious materials.

Mixing Process

Mixing ProcessOnce prepared, the wood fibers are mixed with the chosen binder in precise proportions. The mixing process is critical and must ensure uniform distribution of the binder throughout the wood fibers. This homogeneity is essential for the structural integrity and performance consistency of the panels.

Typically, the mixture comprises about 60% wood fibers and 40% binder by weight, although this ratio can be adjusted based on desired properties. Water is added to activate the binder and facilitate proper adhesion. The temperature and pH levels during mixing must be monitored, as they can influence the setting time and strength development of the binder. Some manufacturers incorporate chemical additives to accelerate curing or to improve resistance to biological degradation.

After mixing, the wet composite is spread into molds or onto continuous production lines where it is formed into panels. The thickness and dimensions are predetermined based on the application requirements. The forming process must ensure that the mixture is evenly distributed to prevent density variations within the panel.

Following formation, the panels are pressed to achieve the desired density and surface finish. Pressing can be carried out using cold or hot presses, though cold pressing is more common for wood wool panels. The pressure applied typically ranges from 0.4 to 1.2 MPa. Adequate pressing ensures that excess water is expelled, and the binder fully encapsulates the wood fibers, which is crucial for the mechanical strength and durability of the panels.

Curing is a vital phase where the binder hydrates and gains strength. The panels are kept under controlled conditions of temperature and humidity to facilitate proper curing. Cement-bonded panels typically require a longer curing period, often up to 28 days, to achieve full strength. However, initial handling strength is usually attained within a few days.

During curing, it is essential to prevent rapid moisture loss, which can cause cracking or reduced strength. This may involve covering the panels or maintaining a humid environment. After curing, the panels undergo drying to reduce the moisture content to acceptable levels, usually below 12%. Proper drying ensures dimensional stability and prevents issues like warping or fungal growth during service.

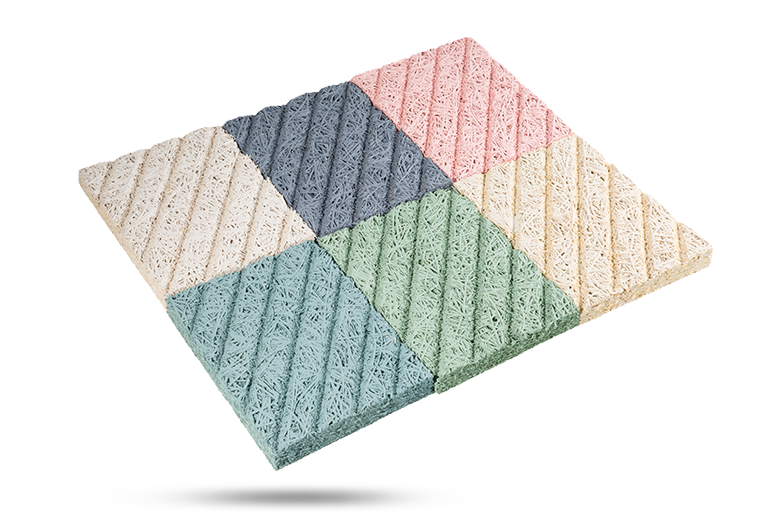

The finishing stage enhances the aesthetic and functional qualities of the wood wool panels. Surface treatments may include sanding to achieve a smooth finish or applying textures for decorative purposes. Edge trimming is performed to meet precise dimensional specifications.

Coatings or sealants may be applied to improve moisture resistance and longevity. Fire retardant finishes can also be incorporated to enhance the panels' fire performance. For applications requiring specific aesthetic outcomes, the panels can be painted or stained in various colors. The versatility of finishing options allows for customization based on architectural requirements.

Quality control is integral throughout the manufacturing process to ensure that the panels meet industry standards and project specifications. Tests are conducted to assess mechanical properties such as flexural strength, compressive strength, and impact resistance. Acoustic properties are evaluated to determine the sound absorption coefficients, which are critical for applications like auditoriums and studios.

Thermal conductivity tests assess the insulation capabilities of the panels, and fire resistance tests confirm compliance with safety regulations. Dimensional checks ensure that the panels adhere to the specified tolerances. Implementing rigorous quality control measures reduces the likelihood of product failure and enhances the reputation of the manufacturer in the competitive market of wood panel production.

Wood wool panels are used extensively in construction due to their multifunctional properties. They serve as acoustic solutions in theaters, lecture halls, and conference rooms, where sound quality is paramount. Their thermal insulation capabilities make them suitable for exterior walls and roofing systems, contributing to energy efficiency in buildings.

In addition to functional uses, wood wool panels are favored for aesthetic applications. Their natural texture adds warmth and character to interior designs. They are also used in prefabricated buildings due to their lightweight nature and ease of installation. The panels' compatibility with other building materials enhances their versatility, making them a valuable component in modern construction practices.

Wood wool panels are considered environmentally friendly as they utilize renewable resources and have a lower carbon footprint compared to synthetic materials. The production process emits relatively low levels of greenhouse gases, especially when using binders like magnesite. Additionally, wood fibers used are often sourced from sustainably managed forests or as by-products from other wood industries, promoting resource efficiency.

The panels are also recyclable and biodegradable, aligning with the principles of sustainable construction. Their use can contribute to green building certifications such as LEED and BREEAM. By opting for wood wool panels, builders and consumers support a circular economy and contribute to reducing the environmental impact of construction activities.

Despite their benefits, manufacturing wood wool panels presents certain challenges. Maintaining consistency in raw material quality can be difficult due to variations in wood species and fiber properties. The reliance on natural materials requires careful supply chain management to ensure availability and sustainability.

Technical challenges include controlling the curing process to prevent defects and achieving the desired balance between strength and weight. Manufacturers must invest in quality equipment and skilled personnel to manage these complexities. Additionally, market competition from alternative materials like fiberglass and foam panels necessitates continuous innovation and cost optimization in the production of Wood Wool Panel.

Recent advancements in technology have led to improved production methods and enhanced panel properties. The use of advanced additives and surface treatments has expanded the functionality of wood wool panels, including increased fire resistance and antimicrobial properties. Innovations in binder formulations have reduced curing times and improved environmental performance.

Automation in manufacturing processes has increased efficiency and consistency in product quality. Computer-aided design and manufacturing (CAD/CAM) systems enable precise control over panel dimensions and patterns, facilitating customization for specific architectural designs. These innovations contribute to the growing popularity and applicability of wood wool panels in the construction industry.

Manufacturers aiming to excel in wood wool panel production should focus on sustainable sourcing of raw materials, ensuring that wood fibers come from certified forests. Implementing strict quality control protocols at each production stage minimizes defects and waste. Investment in research and development is crucial for staying ahead in the market and meeting evolving industry standards.

Collaboration with architects and builders can lead to innovative applications and product improvements. Providing technical support and education to end-users enhances the reputation and adoption of wood wool panels. By prioritizing sustainability, quality, and customer engagement, manufacturers can capitalize on the expanding market for natural and efficient building materials like wood panel.

Wood wool panels represent a fusion of natural materials and modern engineering, offering sustainable solutions for acoustic, thermal, and aesthetic challenges in construction. The manufacturing process, while complex, can be mastered through attention to detail and adherence to best practices. As the industry progresses, the role of wood wool panels is poised to grow, driven by environmental concerns and the demand for high-performance building materials.

By understanding the comprehensive process of creating these panels, stakeholders can make informed decisions that contribute to sustainable development and innovation in construction. The commitment to quality and sustainability in producing Wood Wool Panel products not only meets current market demands but also paves the way for future advancements in building technology.